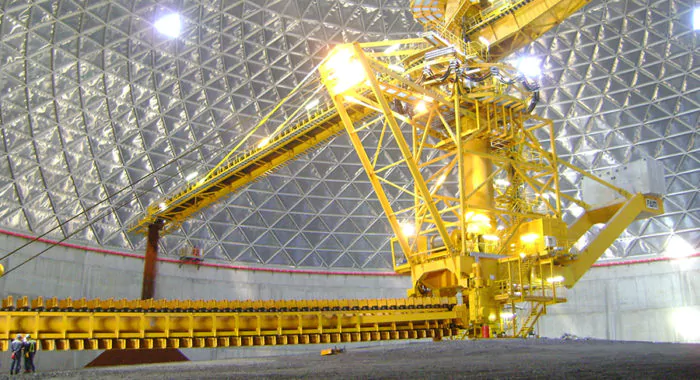

GBM stackers combine robustness, fast operation, and high throughputs. They are designed so the user enjoys the benefits of cost effectiveness, reliability, and eco-friendliness. To meet today’s increasingly strict environmental and safety requirements, GBM stackers are generally equipped with all the necessary precautionary equipment and systems to minimize the impact of noise, dust emissions, etc. on operators and the surroundings.