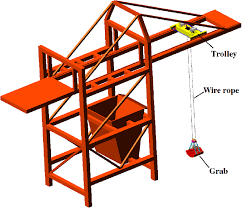

GBM port crane/harbor crane with its experience on port handling, applies for bulk material ship unloading several years. The wire slinged crane with reinforced beam proposed widely by GBM, which has great performance and economical investment.

With its crane technology, GBM combines the reinforced crane with the gantry track mechanism to produce a light weight and small space multi-functional port mobile crane. This series of gantry slewing mobile cargo cranes are not only suitable for loading and unloading of bulk cargo, but also suitable for containers, bulk cargo and cargo in marine and inland ports. The working device can cooperate with all kinds of lifting tools, grab and hook; the portal track mechanism can be changed into a fixed base.