In applications involving smaller flow rates and/or smaller particle sizes, we are able to configure machines in such a manner in which the bucket-wheel is located below the bridge.

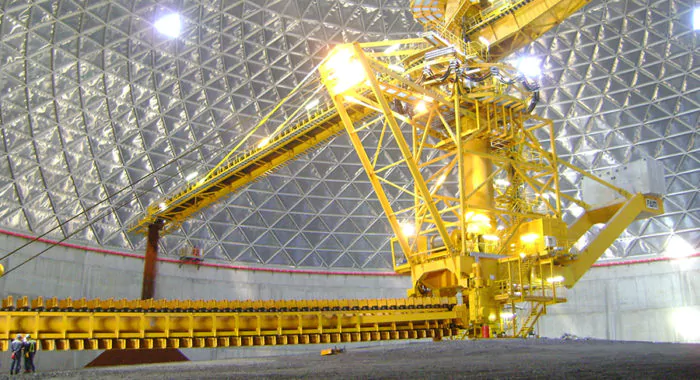

Where higher flow rates and/or larger particle sizes are required, we strongly suggest a machine configuration in which the bridge is mounted through the bucket-wheel. In this manner, power transmission between bucket-wheel trolley and bridge is enhanced which has a positive effect on machine life.

A number of further configurations are also able to be specified, ranging from the number of mounted bucket-wheel trolleys to the manner in which they are arranged. Machines employing two bucket-wheel trolleys are able to achieve a higher reclamation rate, whilst also achieving greater material homogenization at lower flow rate fluctuations. When installing two bucket-wheel trolleys, the trolleys can be mechanically linked so that they both share a common trolley drive system. In applications where very high flow rates are required and/or where very wide stockpiles are employed, we prefer to install each bucket-wheel trolley with their own drive system. A trolley speed controller, developed in-house by GBM, is then employed as this increases interaction efficiency between the two bucket-wheel trolleys.

We are also able to provide bridge bucket-wheel reclaimers for one or two directional reclaiming and all our machines are automated.