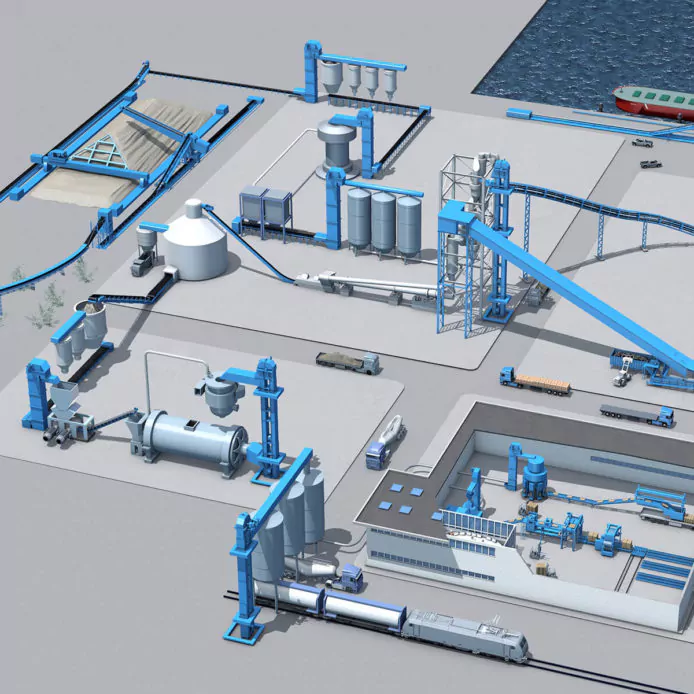

1. One Station Service for material handling, stocking& transporting in Cement plant, GBM Bulk Engineering Co., Ltd. provides the handling solution in cement industry, with capacity of layout designing, machines & system, building construction designing, establishing, and service after sales by EPC Contracting.

2. machines& equipment fabrication, installation and commissioning.

3. Technical supports and handling operation supports with professional expertise.