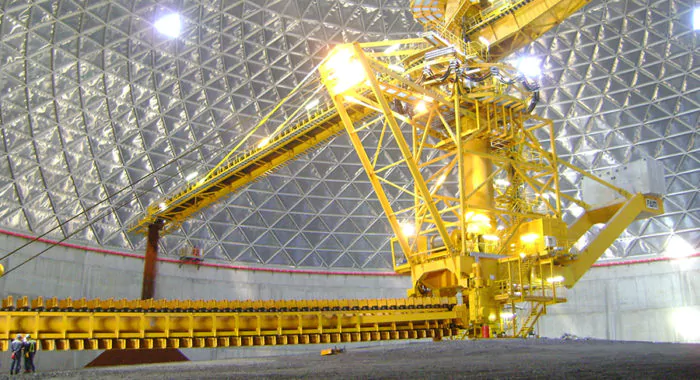

Bucket wheel reclaimers are the ideal means of handling and moving large amounts of bulk materials in the shortest possible time. They can be designed as bucket wheel reclaimers or as combined bucket wheel stacker reclaimers for handling huge volumes of coal, ores, and other materials in ports, power plants, stockyards, or steel plants. Our bucket wheel reclaimers, which are the result of decades of experience and technical competence, combine robustness with outstanding speed and high throughputs. They are used worldwide in the handling of bulk materials such as coal, iron ore, petroleum coke, limestone, bauxite, lignite, phosphate, and other kinds of ore.

GBM bucket wheel reclaimers equipped with bucket wheel booms are used in stockyards dealing with large masses of poorly flowing or extremely heavy bulk materials.

Our bucket wheel reclaimers primarily consist of a slewable superstructure and a rail-mounted base. Both the bucket wheel boom and the counterweight boom are hinge-mounted on the superstructure and guyed with ropes or tiebacks via a pylon.

The bucket wheel boom is raised and lowered by means of rope winches or hydraulic cylinders.